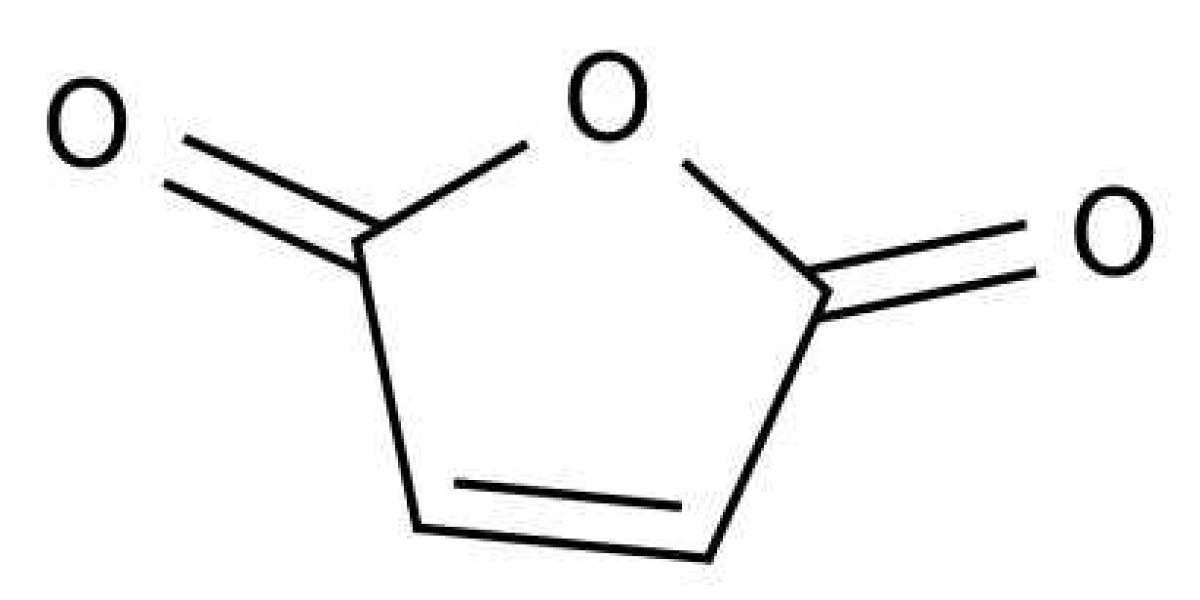

A monochloro-substituted aliphatic alcohol containing 3-8 carbon atoms, a copper compound and a zinc compound are added to maleic anhydride to prevent discoloration of the maleic anhydride. Deterioration of the quality of the maleic anhydride can be inhibited when it is stored for a long period of time or heat-melted.

TECHNICAL FIELD

The present invention relates to a method of preventing maleic anhydride from discoloring and more particularly, to a method of improving its thermal stability and preventing discoloration of maleic anhydride when stored for a long period of time and heat-melted.

BACKGROUND ART

Maleic anhydride is a typical unsaturated dibasic acid obtainable by the catalytic oxidation of benzene or a fraction of hydrocarbons containing 4 carbon atoms (hereinafter referred to as the C4 fraction). Maleic anhydride has two carboxyl groups in the form of acid anhydride and a highly reactive double bond. Therefore, various chemical reactions can be effected by using maleic anhydride.

Maleic anhydride is usually produced by catalytically oxidizing benzene or the C4 fraction in a vapor phase and distilling the resulting reaction products.

However, the maleic anhydride thus obtained by distillation still contains trace amounts of impurities that are difficult to separate such as oxidation by-products and the like. Therefore, the thus-obtained maleic anhydride lacks thermal stability and has a tendency to become discolored when heat-melted. This tendency becomes marked when it is stored for a long period of time. This discoloration upon heat-melting exerts adverse effects on the quality of secondary products produced from maleic anhydride and remarkably impairs their commercial value.

It is therefore strictly required that maleic anhydride for industrial use be free from the discoloration phenomenon at the time of heat-melting and during storage for a long period of time.

In view of the above, various methods have been proposed for the prevention of the discoloration of maleic anhydride. The present inventors proposed a method for improving the thermal stability of maleic anhydride by adding n-propyl gallate, cuprous chloride and zinc chloride to maleic anhydride.

However, the prior methods are still insufficient to meet the severe requirements in quality of these days when maleic anhydride is stored in a solid state for a long period of time. Additives known in the prior art such as phenols and catechols have such a tendency that the additives per se become a cause for discoloring if used in large quantities. In addition, phenols and catechols also have such disadvantages that they may be rendered ineffective with the lapse of time by external factors such as light, oxygen, and the like. Studies have therefore been made in search of excellent color stabilizers for maleic anhydride which can be free from such factors, in particular, discoloration at elevated temperatures.