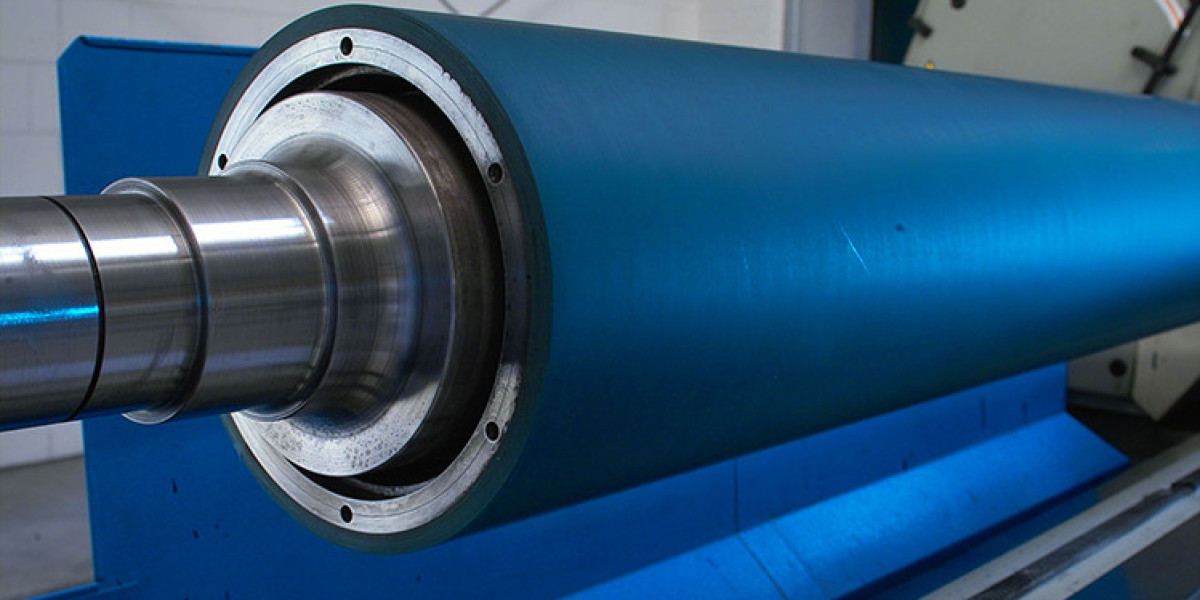

In the realm of construction, where precision and efficiency are paramount, tools like fabric rollers play a crucial role in achieving high-quality results. These rollers, often overlooked in favor of more conspicuous equipment, serve as indispensable assets in various stages of construction projects, offering benefits that extend far beyond their modest appearance.

Understanding Construction Fabric Rollers

Construction Fabric Rollers http://gtroller.ca/, also known as roller sleeves or roller covers, are cylindrical tools typically made from materials like foam, polyester, microfiber, or natural fibers such as wool or mohair. These materials are chosen based on their ability to hold and distribute paint, coatings, or adhesives effectively onto surfaces. The roller sleeve attaches to a handle or roller frame, allowing construction workers to apply materials evenly across various substrates, from walls and ceilings to floors and exteriors.

Applications and Versatility

The versatility of fabric rollers makes them indispensable in a wide range of construction tasks:

Paint Application: Fabric rollers are commonly used for applying paint on walls and ceilings. The absorbency and nap (the surface texture of the roller) of the roller sleeve determine its suitability for different types of paints and surfaces. For example, smooth surfaces often require short nap rollers, while textured surfaces benefit from longer nap rollers that can reach into crevices.

Coating and Sealant Application: Beyond paint, fabric rollers excel in applying coatings such as primers, sealants, and varnishes. Their ability to hold and release materials evenly ensures consistent coverage, which is essential for achieving a durable and aesthetically pleasing finish.

Adhesive and Resin Application: In specialized construction tasks such as flooring installation or fiberglass application, fabric rollers are used to evenly spread adhesives or resin materials. This ensures proper bonding and minimizes waste, saving time and resources during installation.

Advantages of Fabric Rollers

The adoption of fabric rollers in construction projects offers several advantages:

Efficiency: Fabric rollers cover larger surface areas quickly, reducing application time compared to traditional brushes.

Uniformity: The even distribution of materials achieved with fabric rollers results in a more uniform finish, enhancing the overall quality of the project.

Cost-effectiveness: By minimizing wastage and ensuring proper material application, fabric rollers contribute to cost savings over time.

Versatility: Available in various sizes and nap lengths, fabric rollers can be tailored to suit different project requirements, from intricate detailing to large-scale surface coverage.

Choosing the Right Fabric Roller

Selecting the appropriate fabric roller depends on factors such as the type of material being applied, the texture of the surface, and the desired finish. Key considerations include:

Nap Length: Longer naps are suitable for rough surfaces, while shorter naps are ideal for smooth surfaces.

Material Compatibility: Ensure the roller sleeve material is compatible with the specific paint, coating, or adhesive being used to avoid performance issues.

Size: Match the roller size to the surface area for efficient coverage and maneuverability.

Conclusion

In conclusion, while often overshadowed by larger construction equipment, fabric rollers play a crucial role in achieving efficient, precise, and high-quality results across a variety of construction applications. Their ability to evenly distribute paints, coatings, adhesives, and other materials not only enhances the aesthetic appeal of finished projects but also improves overall project efficiency and cost-effectiveness. As construction practices evolve, fabric rollers remain indispensable tools, offering reliability and versatility to construction professionals worldwide.